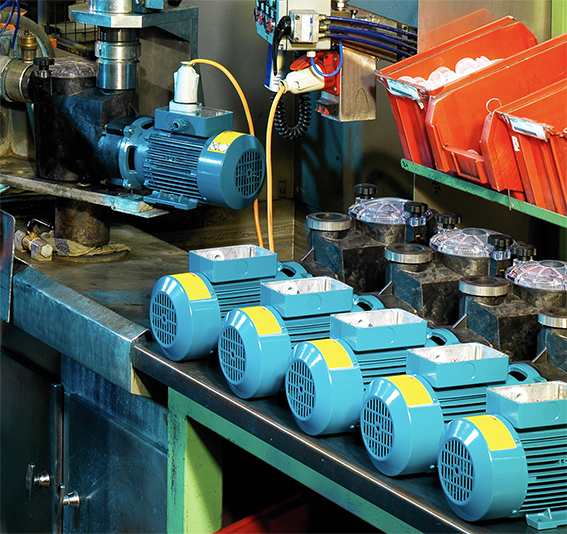

A characteristic that has always marked Calpeda production is the test phase, which is extended to all our products.

It is important to highlight that when we speak about testing we do not just mean the different control protocols relative to design, the assembly procedures and the compliance of the individual parts.

What guarantees the reliability of every product we make, even special execution, and which is an authentic Calpeda trademark, is the hydraulical test carried out on each pump at the end of the assembly phase. It is precisely this additional passage that guarantees production quality safety, and also that the performances are as expected.

Flexibility and programming allow us to insert the test at the end of the line as an indispensable production process rule, and so offer all our clients this important additional value.

The data used to carry out the test come from the test room.

An ideal continuation of the R&D department, the test room has played an extremely important part in Calpeda right from the very start. Provided with the latest measuring and data acquisition tools, it has been enriched over time by cutting-edge systems.

Today it has a 12-metre well for priming and NPSH tests, a test system for the circulating pumps and the vertical multi-stage pumps, a test tank for small pumps, two test systems for pump suction and positive suction head operations, and two continuity rooms for testing pumps in different stress cycles, in extreme conditions conditions and over very long periods.

In short, from the test room to the test bench, each pump is fully tested before leaving our factory. A first simple equation begins here which, together with others we will give you, explains our particular approach to the product: Calpeda=100% Hydraulic Test!